As devices come to be significantly complex and small, the need for top quality PCB assembly manufacturers has actually surged. When reviewing PCB assembly, it is vital to understand not only the procedures involved but additionally how to choose the best PCB assembly manufacturer to ensure that the final item fulfills the highest requirements of top quality and dependability.

The PCB assembly procedure contains numerous vital actions, including prototyping, assembly, and design. Designing a PCB involves producing a schematic diagram that describes just how the different components will certainly get in touch with each other. This is a critical step, as errors in the style can cause damaged items. As soon as the layout is wrapped up, a model is typically created to test capability. After extensive testing and necessary models on the prototype, production can commence.

One essential aspect of PCB assembly is surface place modern technology (SMT), an approach that has actually reinvented the production process by allowing for the installing of parts straight onto the surface area of the PCB. Another usual approach is through-hole technology, where parts are put into openings on the PCB and soldered in area.

When selecting a PCB assembly manufacturer, different elements should be thought about to make sure the best possible end result. A credible manufacturer ought to have a tested track record of supplying top quality items and superb consumer service.

The best PCB assembly manufacturers stay at the center of technology, providing sophisticated manufacturing processes and equipment. The most current machinery can considerably improve the precision and speed of PCB assembly, eventually guaranteeing a higher high quality end product.

Price is an additional essential factor to consider when selecting a PCB assembly manufacturer. It is wise to get quotes from numerous producers and contrast not simply the pricing yet also what is included in each quote.

Lead time is likewise a crucial aspect to take into consideration. In today's hectic market, the capacity to supply rapidly can provide a significant competitive advantage. It is vital to review timelines ahead of time and have a clear understanding of the keep best pcba manufacturer's ability to fulfill target dates. Hold-ups in assembly can have plunging effects on product launches and supply chain monitoring, which can ultimately affect a firm's success.

As soon as an appropriate PCB assembly manufacturer has been chosen, the cooperation should start with open interaction. Early and clear discussion about assumptions, layout specs, and top quality assurance actions can help prevent possible problems in the future. Taking part in a collaborative partnership additionally enables for comments that can bring about continuous enhancement and innovation. Manufacturers that want to work closely with customers to settle issues or make enhancements show a trusted partnership.

Quality control procedures should be in place from the early stages of assembly, consisting of evaluations, screening, and verification procedures. Using automated optical inspection (AOI) can help catch flaws that might not be noticeable to the nude eye, while functional screening can confirm that the assembled PCB performs correctly in real-world conditions.

Fads such as miniaturization, enhanced intricacy, and the requirement for personalization are driving advancements in PCB layout and assembly processes. Remaining updated on these advancements allows a business to pick a PCB assembly manufacturer that doesn't just fulfill current requirements yet is also prepared for future demands.

Sustainability is coming to be an increasingly crucial facet of electronics producing. As businesses and consumers alike end up being extra eco conscious, collaborating with a PCB assembly manufacturer that prioritizes green processes can improve your brand name's credibility. This can consist of using lead-free solder, reusing programs, and responsible waste administration techniques.

When talking about PCB assembly is the potential for recurring assistance and service after the assembly is complete, another essential consideration. A high quality manufacturer does not simply supply the set up PCB and leave; they should be offered for support with any problems that may develop post-delivery. Whether it's fixing, fixings, or upgrades, having a relied on partner that can offer recurring support can be invaluable in maintaining the durability and performance of digital products.

Looking ahead, embracing technical advancements and promoting solid relationships with PCB assembly makers will certainly be essential to prospering in the fast-evolving electronic devices landscape. As market demands remain to move, firms that prioritize top notch assembly procedures, technology, and a strong collaboration with their manufacturers will stand apart. The merging of emerging innovations, consumer expectations, and sustainability will certainly define the future of PCB assembly. It is vital that organizations remain responsive and active to these adjustments, guaranteeing they can adjust their techniques to take advantage of brand-new possibilities.

In conclusion, browsing the world of PCB assembly calls for a detailed understanding of the manufacturing procedure, a calculated method to picking the best PCB assembly manufacturer, and a dedication to top quality and advancement. Therefore, selecting to work with a respectable PCB assembly manufacturer is not simply a technological choice; it is a critical organization selection that can drive a brand name towards lasting success.

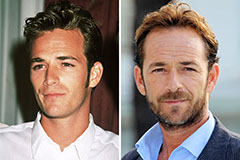

Luke Perry Then & Now!

Luke Perry Then & Now! Michael Oliver Then & Now!

Michael Oliver Then & Now! Marcus Jordan Then & Now!

Marcus Jordan Then & Now! Nancy Kerrigan Then & Now!

Nancy Kerrigan Then & Now! Brooke Shields Then & Now!

Brooke Shields Then & Now!